|

Ningbo HS Machinery Parts Factory

|

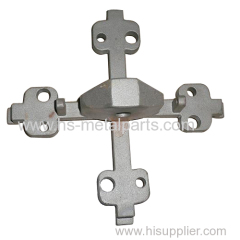

Rock drilling machines investment casting parts

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

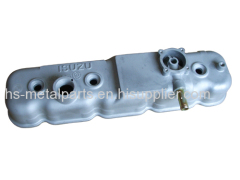

Materials: Alloy steel,catbon steel, gray iron or ductile iron

Process: Water glass casting and machined

Finish: anti-rust oil

Certificate: ISO9001

Material capabilities: Alloy steel, Carbon steel, High resistant stainless steel, Ductile iron, High chromium iron, Gray iron, brass, bronze etc.

Casting technique: Investment casting( Lost wax casting), precision casting, lost foam casting) and steel sand casting process.

Procedure: Casting, Surface treatment, Heat treatment, Machining, Polishing, Packing and delivery

surface treatment after casting, such as machining, polishing, plating, etc.

Software for specification drawing: PDE, Solid work, ProE, JPG, Auto CAD

Place of origin: Ningbo,China

quality: Strict material inspection, Exact dimension control, Promote quote and delivery guarantee, 100% quality control, OEM service, ISO 9001:2008

Machining Parts Materials | Aluminium ,Aluminum alloy ,Zinc ,Zinc alloy ,Stainless steel ,Mild steel ,Alloy steel ,Cooper ,Brass ,ect. |

Tolerance | 0.05-0.1mm |

Application | · Medical parts |

Machining devices | 1) 1 Fadel CNC Vertical Machine Center ,with tool changers 2) 3 CNC Robodrills ,Fanuc controls ,with pallet changers 3) 4 CNC Robodrills ,Fanuc controls 4) 1 Okoma CNC Lathe 5) 5 Dedicated Machine Centers ,Amplifier Housings ,Multiple drill /tap /bore operations 6) 2 Dedicated Drill & Tap Machine Centers ,ADC Amplifier Housings 7) 1 Dedicated Tap Centers, Fiber Housing 8) 3 Dedicated Tap Centers, Fiber Housing 9) 4 Natco Multi Spindle Drill/Tap Machines 10) 24 Spindle Capacity 11) 3 Bridgeport Milling Machines |

Production procedure | 1.Designing drawing |

Certification | ISO9001:2008 |

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminum alloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.