|

Ningbo HS Machinery Parts Factory

|

304 stainless steel investment castings

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Stainless steel precision lox wax investment casting

Accept drawings:Pro/E, Auto CAD, Solid work, PDF etc.

Small quantity as samples are accepted

stainless steel precision lox wax investment casting introduction:

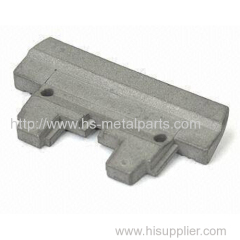

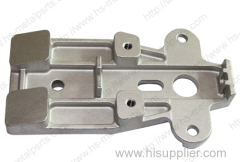

Main process:Water soluble lost wax pattern, water glass and silica sol investment casting

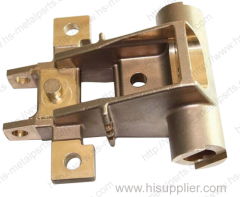

Materials:Stainless steel/1.4308 (CF8), 1.4408 (CF8M), 1.4301 (SS304), 1.4401 (SS316), and 1.4404 (SS316L)

Annual output: 3,600T

Applications: valves, pumps and impellers, engineering vehicles, heat-resistant steel parts, railway locomotive

Delivery :45--60 days

Minimum order: 20-100 pieces

Certificate:Passed the ISO 9001:2008

Machining process is available

Customized OEM parts specifications are available (drawings or samples)

Complex geometry is available

process lines are adopted.

Process | Material Capacity | Standard | |

Grey Iron, Ductile Iron, Malleable Iron, Stainless steel, Carbon steel, Aluminum, brass, bronze, copper, Alloy steel | ASTM BS JIS DIN etc. | ||

Furan Resin sand | |||

Gold Harden Resin sand | |||

Sodium Silicone( Water glass) | Stainless steel, Carbon steel, Alloy steel, Bronze, brass, Aluminum | ||

Forging | Hammer Forging | Stainless steel, carbon steel, Alloy steel, brass, Aluminum | |

Die Forging | |||

Roll Forging | |||

Stamping | All Metal material | ||

Machining | |||

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminumalloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.