|

Ningbo HS Machinery Parts Factory

|

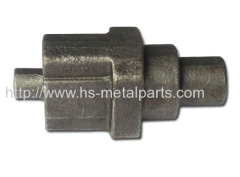

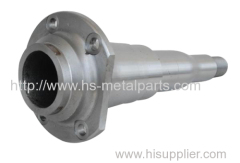

Hot forged parts for CNC machining

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Hot Forging Parts.

2.Material:According to customers' request

3.Weight:1-100kg

4.Standard:JIS,DIN,ASTM,BS.

5.OEM service.

Hot forging and machining parts

1)Material:

Carbon Steel, Alloy Steel, Stainless Steel and so on.

2)Standard:

GB, JIS, AISI, SAE, ASTM/ASME, EN, DIN.

3)OEM and Customized service offered

4)Surface treatment facilities:

shot-blast cleaning room.

5)Process:

Forging/Casting – Normalizing & Tempering – Proof Machining- Quenching & Tempering – Finish Machining.

6)Heat treatment equipments:

normalizing furnaces, quenching-tempering line.

7)Payment:

30% T/T in advance, Or L/C.

8)Measuring & testing equipment:

Projecting profile, roughness tester, hardness tester, concentricity tester ect.

9)Size:

Special designs are available. Making according to clients' demand.

10)Packing:

Wooden packing, container packing or as per customers' requests.

11) Max Weight:

55T .

12)Inspection:

In-house and the third party.

13)Deliver Time:

10~45 days from order.

14)Industrial categories:

heavy-duty truck industry/auto industry/ construction machine industry/general machine/others.

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminumalloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.