|

Ningbo HS Machinery Parts Factory

|

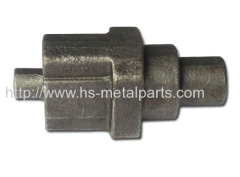

Hot Die forging parts

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

-Auto lathe, CNC machining, CNC turning, CNC cutting, CNC milling, threading, tapping, drilling, etc.

-Carbon Alloy, Stainless steel, Alloy steel etc

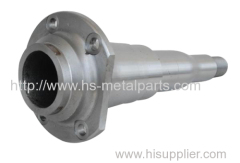

Named | Forging and CNC Machining Parts and Precision CNC Machining Parts for Carbon steel/Aluminum/Brass/Stainless Steel |

Country/Region | China(mainland) |

City & Province | Ningbo/ Zhejiang |

Company | HS Machinery Parts |

Supply ability | 10000 Piece/Pieces per Month |

Package | Woonden case or as per request |

Delivery date | 45--60 Days after the confirmation of sample |

Port | Ningbo |

Material | Carbon steel |

Application | Industry, machinery, auto parts, etc |

Dinmensions | As requirement |

CNC machining, Sheet Metal Fabrication, CNC Machining Parts, CNC Lathe Parts, CNC Machined Part, turning parts, milling parts.

Material: Aluminium, stainless steel, tool steel, brass, copper, bronze, tungsten carbide, HSS, POM, titanium etc

Ningbo HS Machinery Parts Factory can customize strictly the mold components and CNC machining parts according to customer's CAD and 3D drawings.

Precision machining parts, Turning parts, mold insert, machine parts, lathing parts, machinery parts, wire EDM components, CNC milling accessories, hardware fittings, metal forming parts, carbide parts, aluminum alloys parts, Automotive parts, CNC grinding components, etc.

OEM&ODM are welcomed.

These products are showed here only to present the capability of our business activities, we can produced according to your drawings or sample.

It would be our proud to serve you at once we receive your valued enquiry with detailed specification and drawings, and we will submit our competitive offer ASAP.

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminumalloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.