|

Ningbo HS Machinery Parts Factory

|

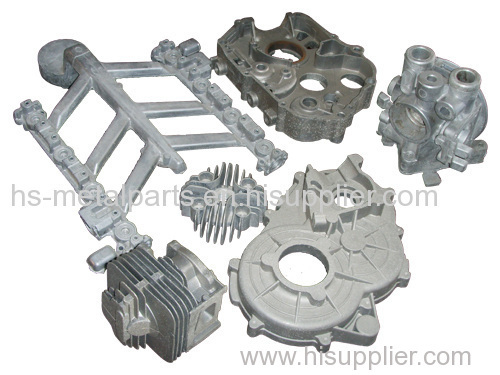

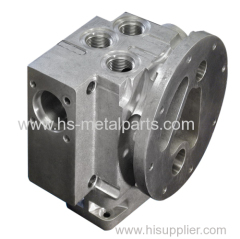

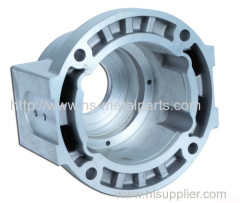

Die casting aluminum for motor

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

We can make products to your exact specifications from our

optimized processes

Very rigorous quality control

Professional service team

1) Material:carbon steel:1010,1020,1030..... ; low alloy steel:4130, 4140,4150.....

2) Standard: JIS, DIN, ASTM, BS

3) We are ISO9001:2000 certified

4) Process: sand casting, investment casting, die casting,

permanent mold casting

5) We can make products to your exact specifications from our

optimized processes

6) Very rigorous quality control.

Die casting aluminum for motor

What is our difference from others ?

1.Product have no shortage of material ,cold material,waterlines,shink etc phenomenon

2. Dimensional tolerances can be controlled in the range of 2-5 microns .

3.Cooperation with Listed companies--Comix commercial equipment Co.,ltd for 4 years.

4.Five years of experience in production of aluminum die casting .

5.. More than a decade of experience in mold manufacturing.

6.mold to finished product is one-stop service

7.Obtained ISO9001 certification.

Products and services provided | Lost wax casting / Investment casting / Precision casting/Steel casting Precision machining Assembly Casting design and technical supports |

Material selected | Carbon steel Alloy steel Stainless steel Ductile iron Grey iron Brass Bronze Aluminum |

Second operation available | Galvanizing / Zinc plating Polishing Paint / electrophoretic paint Assembly |

Inspection | Inhouse inspection Material reports and dimension reports are provided every batch production. Third party inspection is also available upon request. |

Packing | Packed in cartons / cardboard box Packed in fumigating free plywood cases More information can be provided upon request. |

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminum alloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.