|

Ningbo HS Machinery Parts Factory

|

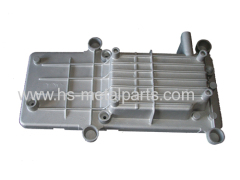

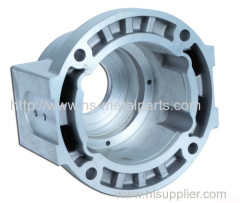

Aluminum casting with oxidation

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Material:Aluminum

process: casting and machining

finish: oxidation

Place of Origin: Ningbo China

Welcome to send us your drawings and requirement

Product Description

Product Description

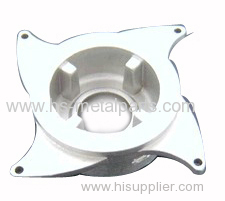

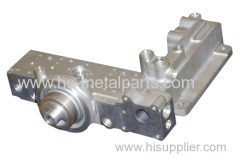

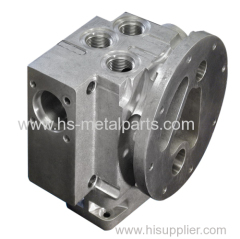

1) Product Name:Aluminum die casting

2) Material: Aluminum alloy

3) Applicable Industry: Auto parts, motor shell, pump parts, machinery parts,lamp chimney.

4) Applied file format: Auto CAD, Solid work;

Manufacture Process

1) Process: Die Casting + Machining

2)Secondary Machining: CNC turning, milling, drilling, grinding, assembly to Packing

3) Surface Finish: Chrome plating, sandblasting, painting, anodizing, powder coating, electrophoresis

Company advantage

1.ISO 9001:2008 certified

2. Advanced equipment and excellent R&D Team

3. Highly skilled manufacturing process

4. A broad variety of ODM&OEM product range

5. Strict quality Control System

Company Profile:

With plentiful experience and skillful technique, It has the full capacity to produce the best aluminium die casting as per our customers drawing or sample and we enjoy a good reputation in domestic and overseas market.

Process | Material Capacity | Standard | |

Grey Iron, Ductile Iron, Malleable Iron, Stainless steel, Carbon steel, Aluminum, brass, bronze, copper, Alloy steel | ASTM BS JIS DIN etc. | ||

Furan Resin sand | |||

Gold Harden Resin sand | |||

Sodium Silicone( Water glass) | Stainless steel, Carbon steel, Alloy steel, Bronze, brass, Aluminum | ||

Forging | Hammer Forging | Stainless steel, carbon steel, Alloy steel, brass, Aluminum | |

Die Forging | |||

Roll Forging | |||

Stamping | All Metal material | ||

Machining | |||

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminumalloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.