|

Ningbo HS Machinery Parts Factory

|

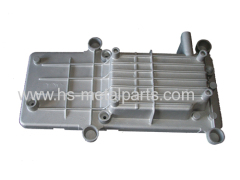

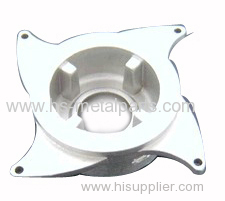

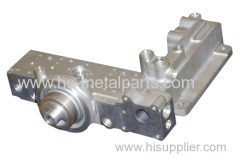

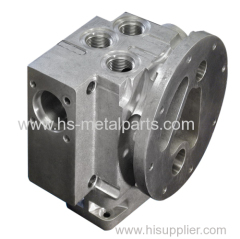

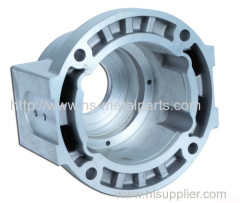

Aluminum Casting For Auto

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Brand Name: OEM ;

Material:Ironaluminum injection die casting, Carbon steel, Alloy steel & Stainless Steel

Die Casting

1.Material: carbon steel, alloy steel, stainless steel, aluminum alloy, zinc alloy, brass, gray iron, nodular cast iron, ductile Iron or other specified

2.Standard: ASTM, AISI, BS, DIN, JIS, NF

3.Process: investment casting, Lost wax Casting , sand casting

4.Machining: turning , milling, drilling, grinding, threading, CNC machining, etc.

5.Finishing: sand blasting, polishing, plating, ac id treatment, anodizing, painting and PVC powder coating

6.Certificate: ISO 9001-2000; ISO/TS16949

7.Application: Automotive & Transportation Parts; Fitness Equipment; Mining Machinery; General Industrial Equipment; Home Appliance; architectural parts etc.

Named | Automotive parts by casting |

Process | Investment casting + CNC machining |

Material | grey iron , alloy steel, stainless steel etc. |

Material Standard | ASTM, DIN , JIS, BS |

Surface | Anti-rust oil, galvanized , painting, powder coating, sand blast etc. |

Weight | from 0.5kg to 100kg |

Machining facility | CNC center , NC machines, turning machines, drilling machines , milling machines, grinding machines |

Applied Software | ProE (.igs , .stp) , Auto CAD , PDF are available |

Heat Treatment | Annealing, tempering , normalizing, solid solution , QT |

Measuring Tool | CMM , vernier caliper, depth caliper, micrometer, pin gauge, thread gauge , height gauge |

QC system | Sampling inspection ,100% inspection before shipment |

Package | Wooden case or as client's request |

Payment Terms | T/T , L/C at sight |

Shipment terms | Ningbo |

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminum alloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.