|

Ningbo HS Machinery Parts Factory

|

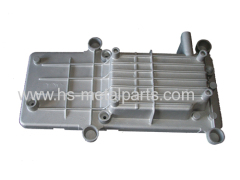

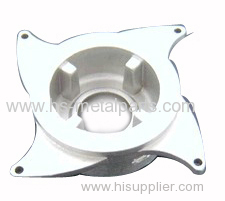

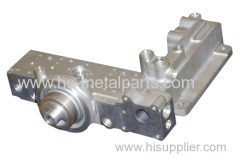

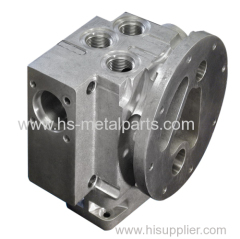

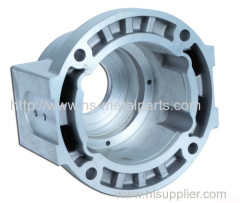

Aluminum gravity casting and machined parts

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Aluminum: LM2, LM6, LM9 etc.

Process: gravity casting and machined

Finish: Oxidation

Size: as drawing

Reasonable quotation with Good credit

Metarial: Aluminum:

Aluminum Alloy | Reference Standard | ANSI AA | BS1490 | DIN1725/2 | JIS |

413.2 | American | 413.2 | LM6 | GD-ALSi12 | |

A360 | American | A360.1 | LM9 | ADC3 | |

A380 | American | A380.0 | LM24 | GD-AISi8Cu3 | ADC10 |

384 | American | 384 | ADC12 | ||

ADC12 | Japanese | 383.0/384.0 | ADC12 | ||

GD-AISi9Cu3 | German | LM2 | GD-AISi9Cu3 | ||

GD-AISi12(Cu) | German | A413.0 | LM20 | GD-AISi12(Cu) | ADC1 |

Casting:For Aluminum castings we can use die casting, gravity casting, sand casting and permanent steel mould casting processses for options according to customer product performance and requirements.

Features:

1) Materials: Carbon Steel, Alloy steel, Stainless steel, High Manganese steel, Gray Iron, Ductile iron, Resistance cast iron, High Cr Cast iron, Resistance steel, and etc. Customer's drawings are accepted

2) Main equipment: Wax injection, CNC-machine, machine-center, Heat treatment Furnace

3) Surface treatment: After casting, we can do machining, polishing, oiled (rust-proof), zinc, nickel, chrome plating, hot galvanized, painted.

4)Suitable for: These products are for the power generation industry, pressure vessels, components for commercial nuclear reactors, Press components, mining equipment components, marine propulsion shafting, heavy construction machine, agricultural machine, Plastic Extrusion Equipment and custom forgings.

5)Software for specification drawings: PDF, Auto CAD, Solid work

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminum alloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.