|

Ningbo HS Machinery Parts Factory

|

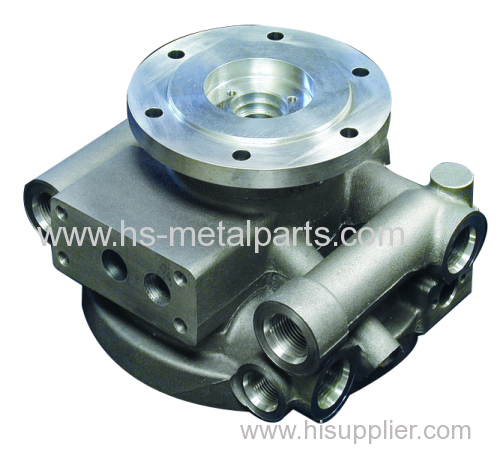

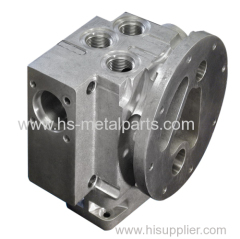

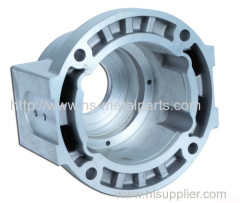

Laboratory Equipment Aluminum sand casting parts

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

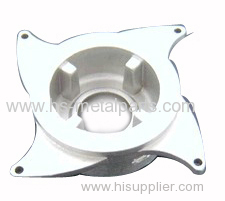

1) Material:Aluminum

2)Place of Origin: Ningbo China

3)Standard: JIS,DIN,ASTM,BS

4)OEM service are acceptable!

1 Technology | precision casting; investment casting; water glass; lost wax |

2 Standards | ASTM, AISI, BS, DIN, JIS, NF |

3 weight range | 0.1KG- 150KG |

4 Capacity | 6,000Tons/Year or 500 Tons/Month |

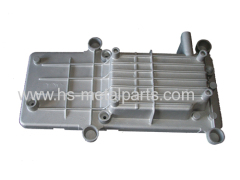

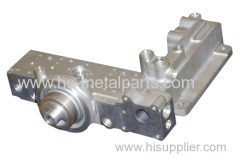

5 application | Auto parts,valves ,valves bodys, mine parts, Ag Machinery Partsconstruction and machinery parts, metallurgy tools, shipping parts, etc |

6 Inspection &test | Foundry in home ,third part inspection,Material, Dimensions ,heat treatment report ,UT ,MT, X-ray .Mechanical Properties, ect |

7 Quality control | ISO 9001:2008, CE ,inner control. 100% inspection for parts |

8 Casting equipments | Shotblastingmachine,steamboiler,aircompressor,electricinductionfurnace,grindingmachine,peeningmachine,drillingmachine,3D paralleling vibrating casting machine,arc welding machine, wax injection machine,spraying sand machine,etc; |

9 Machining equipment | drilling machine,vertical drilling,numerical control lathe, facing machine,rectification arc welding machine,etc |

Prototype has many advantages, including:

· Improved production lead times

· Proves out both design and manufacturing processes

· Minimizes cost and overall risks in new designs

· Offers an economical forum for product improvements

· Presents opportunities for early cost reductions

· Limits the costs of engineering changes

· Allows for incremental steps in development

· Enhances sales and marketing of "new concepts"

· Accelerates the "time to market"

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminumalloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.