|

Ningbo HS Machinery Parts Factory

|

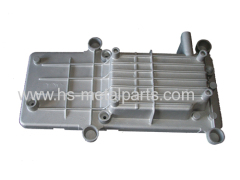

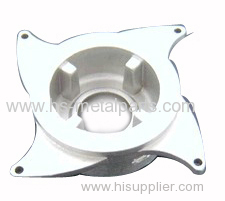

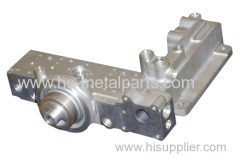

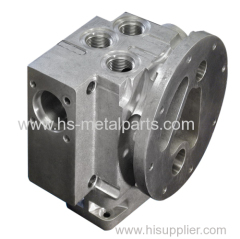

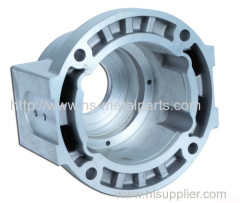

Sand casting industry equpiment parts

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Reasonable quotation

Excellent quality,Tolerance:0.05-0.1mm

Stable delivery time ,45-60 days

Professional service team, >= 10 years

Good credit

Haoshuo is a custom sand cast foundry producing industrial grade, our castings with superior machining properties and surface finishes. We offer some of the shortest production lead times in our industry on a consistent basis.

We serve a variety of industries including...

Hydraulics | Pneumatics | Fluid Controls |

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. Over 70% of all metal castings are produced via a sand casting process.

Sand casting is relatively cheap and sufficiently refractory even for steel foundry use. In addition to the sand, a suitable bonding agent (usually clay) is mixed or occurs with the sand. The mixture is moistened, typically with water, but sometimes with other substances, to develop strength and plasticity of the clay and to make the aggregate suitable for molding. The sand is typically contained in a system of frames or mold boxesknown as a flask. The mold cavities and gate system are created by compacting the sand around models, orpatterns, or carved directly into the sand.

There are six steps in this process:

Place a pattern in sand to create a mold.

Incorporate the pattern and sand in a gating system.

Remove the pattern.

Fill the mold cavity with molten metal.

Allow the metal to cool.

Break away the sand mold and remove the casting.

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminumalloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.