|

Ningbo HS Machinery Parts Factory

|

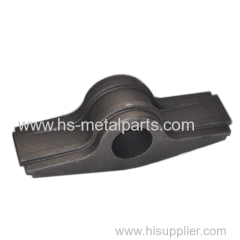

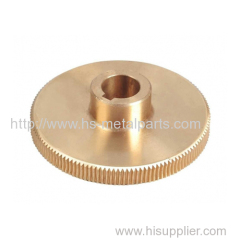

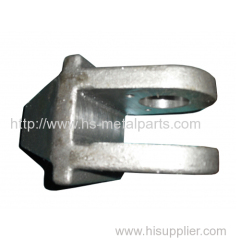

OEM Lost Wax Investment Casting and machining parts

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Materials:carbon steel/ Alloy steel/Stainless stee

Process: Investment casting and drilling, milling etc.

Finish: Zinc Plating ,Chrome Plating

Material: Carbon Steel, Alloy Steel, Stainless Steel, Gray Iron, Ductile Iron, High Cr iron, High Nickel iron, brass, bronze, zinc alloy etc.

Material Standard: ASTM, SAE, ISO, DIN, GB, BS, GOST

Technic: Investment casting, Lost wax casting, Precision casting, Lost foam casting, Water glass casting, Silica sol casting, Sand casting, quartz sand casting technics, Furan resin sand casting, phenolic resin sand casting technices

Second operation: CNC maching, planning, grinding, turning, drilling, milling, threading

available finish: Polishing, zinc plating, chrome plating, polished brass, nickel plating, electrophoresis, dichromate, vibratory milling and electropolish, powder coating, painting, anodization, phosphating.

Process | Investment casting + CNC machining |

Material | grey iron , alloy steel, stainless steel etc. |

Material Standard | ASTM, DIN , JIS, BS |

Surface | Anti-rust oil, galvanized , painting, powder coating, sand blast etc. |

Weight | from 0.5kg to 100kg |

Machining facility | CNC center , NC machines, turning machines, drilling machines , milling machines, grinding machines |

Applied Software | ProE (.igs , .stp) , Auto CAD , PDF are available |

Heat Treatment | Annealing, tempering , normalizing, solid solution , QT |

Measuring Tool | CMM , vernier caliper, depth caliper, micrometer, pin gauge, thread gauge , height gauge |

QC system | Sampling inspection ,100% inspection before shipment |

Package | Wooden case or as client's request |

Payment Terms | T/T , L/C at sight |

Shipment terms | Ningbo |

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminum alloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.