|

Ningbo HS Machinery Parts Factory

|

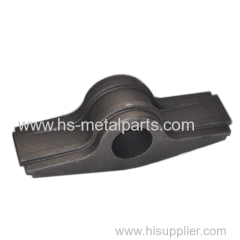

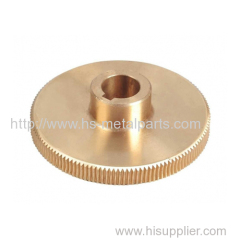

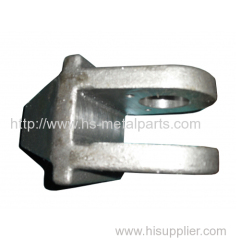

Stainless steel 202 304 316 investment casting auto spare parts

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Max Casting Size: 1000mm

Casting Weight:0.10-100Kg

Dimension Tolerance: CT7

Surface:Oil

Surface Roughness: Ra6.4~12.5

Material | Stainless steel |

Craft | Investment casting |

Finish | Zinc plated, Nickel Zinc |

Color | White or Yellow |

Country/Region | China (Mainland) |

City & Province | Ningbo, Zhenjiang |

Company | Ningbo HS Machinery Parts Factory |

Supply Ability | 10,000 Piece/Pieces per Month |

Minimum Order Quantity | 100 Piece/pieces |

Packaging Details | Corrugated cases Composite material box As special required when order |

Delivery Time | 45-60 days |

Port | Ningbo as usually |

Payment | T/T, L/C |

1) FOB price per piece in USD.

1a) Mold/Tooling cost for each part.

1b)We will produce 2-samples of each parts by courier free of cost.

2) We can supply Country of origin

3) Offer validity 60 days from your quotation date for technical scrutiny and placing the order

A world class manufacturer & supplier of lost wax investment castings in carbon steel and alloy steel, is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry & machining factory. Precision casting parts are exported to markets in Europe, America Australia andJapan. Our company adopts the modern industrial management style, promotes ISO9001: 2008 quality management system . we achieved the win-win situation for company's profit and environment protection.

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminumalloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

In order to your best assurance of all castings will conforming and complying with your specifications, we focus on quality control process. We provide first piece inspections and final casting inspections to verify the quality of the entire production run. Allinvestment casting tools are inspected prior to each issuance to the injection floor. We also can supply chemical, physical, and non-destructive testing such as spectrographic analysis, radiography, fluorescent zyglo, and more. We will work with you to verify we can meet the best testing process for your application.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.