|

Ningbo HS Machinery Parts Factory

|

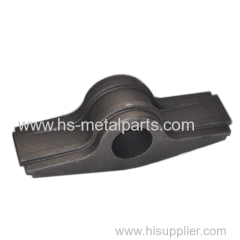

Water glass casting Engineering Machinery components

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Material: Iron

Casting: Sand casting

Surface: spray painting

Application: Engineering Machine

Professional service team, >= 10 years

Good credit

Casting Process:Max Casting

Max Casting Size: 1000mm

Casting Weight:1kg-100Kg

Dimension Tolerance: CT7

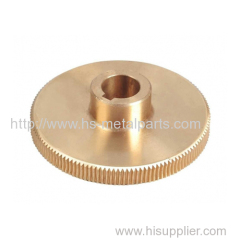

Material: Carbon Steel, Alloy Steel, Stainless Steel, Gray Iron, Ductile Iron, High Cr iron, High Nickel iron, l, brass, bronze, zinc alloy etc.

Technic Investment casting, Lost wax casting, Precision casting, Lost foam casting, Water glass casting, Silica sol casting, Sand casting, quartz sand casting technics, Furan resin sand casting, phenolic resin sand casting technices

Casting tolerance: Lost wax casting Tolerancing Standards :ISO/GB CT7~9; Sand casting

Productivity: 8000 tons

A world class manufacturer & supplier of lost wax investment castings in carbon steel and alloy steel, is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry & machining factory. Precision casting parts are exported to markets in Europe, America Australia andJapan. Our company adopts the modern industrial management style, promotes ISO9001: 2008 quality management system . we achieved the win-win situation for company's profit and environment protection.

Product name | Precision casting Engineering Machinery Parts |

Material | Alloy steel, Carbon steel, High resistant stainless steel, Ductile iron, High chromium iron, Gray iron |

Casting technique | Investment casting( Lost wax casting) |

Casting tolerance | ISO / GB CT 7~ 9 |

Standard | DIN, ASTM,BS, JIS etc. |

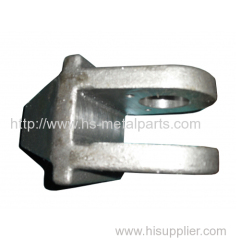

Procedure | Casting, Surface treatment, Heat treatment, Machining, Polishing, Packing and delivery |

Main equipments | Wax injection, CNC-machine, Machine-center, Heat treatment furnace. |

Place of origin | Ningbo,China (Mainland) |

Trade Items | FOB Ningbo, CIF |

Lead time | 30 days after the sample confirmation |

Main market | United States,Canada,UK,Germany, Holland,France,Denmark,Australia,Sweden,Finland,Russia,Spain,Portugal.Italy, etc etc. |

Drawings | JPG, Auto CAD, Pro/E, PDE, Solid work etc. |

Surface treatment | Zinc platting, powder coating, machining, polishing, plating, etc. |

Casting capability | precision casting, investment casting ( lost wax casting, lost foam casting) and steel sand casting |

Main products | Machine parts ( machining parts. Machinery parts) , metalwork ( metal products) Forging parts and stamping parts |

Package detail | Inside is carbon box, outside is wooden box. We also can pack as customer's specific requirement to avoid damage, suitable for sea and air transport. |

quality | Strict material inspection, Exact dimension control, Promote quote and delivery guarantee, 100% quality control, OEM service, ISO 9001:2008 |

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminumalloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.