|

Ningbo HS Machinery Parts Factory

|

Gold Index: 76574

OEM pump investment casting

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

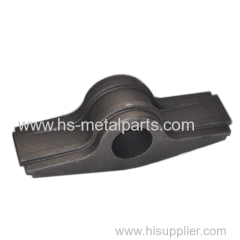

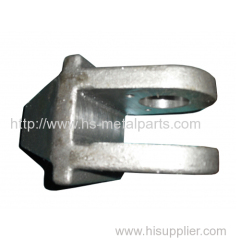

Auto investment casting parts

(1) Materials: iron ,steel ,alloy

(2) Professional service

(3) Best price and quality

(4)OEM Service

investment casting

Material: iron, gray iron, ductile iron, steel, stainless stee,l carbon steel, alloy

Process: sand casting ,investment casting ,die casting and so on

Standard: GB ,ASTM ,DIN ,JIS

Weight range: 500g to 100kg

Casting process: client drawings-pattern-raw casting-maching-packing and delivery

Quality control:

(1) Machinery properties and Chemical components testing after raw casting

(2)Hardness checking after heat treatment

(3)Dimensions testing after maching

Raw casting is the most important ,it is also our strength

1. Production plan will be made according to the production tracking form.

2. During production process, we use advanced inspection equipments, to ensure internal quality of the product. The inspectors will track the quality and duration according to the production tracking form. The inspectors will feedback the problems of the quality and process, and improve quality gradually.

3. We will check the test bar and record relevant information to each bulk.

4. We will send the photos and test data of each step to customers and let them to know the status of their products.

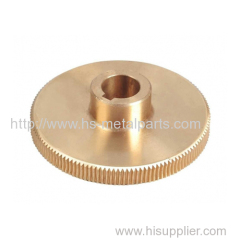

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminumalloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

You May Like:

Product (611)

- Carbon Steel Castings (28)

- Alloy Steel Castings (65)

- Stainless Steel Castings (45)

- Iron Castings (22)

- Aluminum Castings (52)

- Brass Castings (26)

- Bronze Castings (11)

- Forgings (29)

- Stampings (14)

- Machined Parts (17)

- Investment casting (76)

- Sand Casting (27)

- Mining castings (15)

- Agricultural or Farming castings (27)

- trailer or truck casting (25)

- forklift casting (14)

- railway or train casting (14)

- Automotive parts (42)

- Construction castings (15)

- Bucket teeth and adapters (15)

- Flange casting (17)

- Pump casting (15)