|

Ningbo HS Machinery Parts Factory

|

Gold Index: 76574

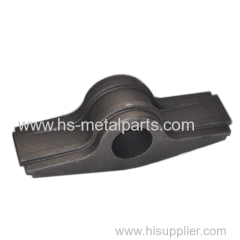

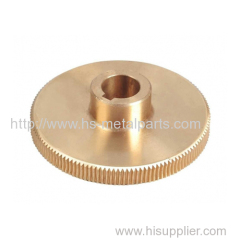

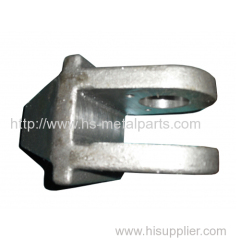

Precision lost investment casting

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1)15 years experience on OEM precision casting

2)ISO9001:2008, CE/PED Certified by TUV

3)small order accepted

The processing, production drawings, technical guidance,precision casting, customer service feedback

Casting content:

All kinds of stainless steel, carbon steel, alloy steel, ductile ironand other precision parts and all kinds of metal products

Process characteristics:

Silica sol shell technology, complex structure formed in a variety of materials, smooth surface

"Because specialty, so the precision", we not only haveprofessional technology and equipment modernization, but also has a "refine on, build a team loyalty", "wisdom, benevolence,letter, Yong, Yan" is the spirit of the future of the enterprise'shuman cast, "cross-world friends in virtue, four creditcustomers". We look forward to your visit!

Materials | Iron, stainless steel, brass, copper, alloy steel,etc. |

Surface treatment | according to drawing |

Making Process | Cutting,Stamping, bending, punching, lubricating, etc. |

Inspection | In-house and third party |

Delivery | 30days Just-in-time manufacturing capability to meet customer's requirement |

Price | FOB Tianjin |

Payment Terms | L/C, T/T |

Packing | 1 Prevent from damage |

2. As per customer's requirements,in perfect condition | |

Application | Precision stamping parts custom made to customer's requirements. |

Remark | For the fast results, when requesting a quote: |

1. Please email or fax us your inquiry with as much information as possible. | |

2. Please include quantities required, material requirements, sketches, drawings |

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminumalloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

You May Like:

Product (611)

- Carbon Steel Castings (28)

- Alloy Steel Castings (65)

- Stainless Steel Castings (45)

- Iron Castings (22)

- Aluminum Castings (52)

- Brass Castings (26)

- Bronze Castings (11)

- Forgings (29)

- Stampings (14)

- Machined Parts (17)

- Investment casting (76)

- Sand Casting (27)

- Mining castings (15)

- Agricultural or Farming castings (27)

- trailer or truck casting (25)

- forklift casting (14)

- railway or train casting (14)

- Automotive parts (42)

- Construction castings (15)

- Bucket teeth and adapters (15)

- Flange casting (17)

- Pump casting (15)