|

Ningbo HS Machinery Parts Factory

|

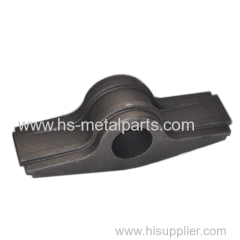

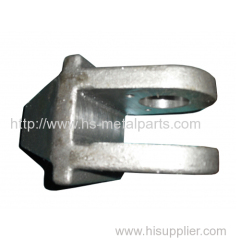

Auto parts investment casting

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

(1) Materials: iron ,steel ,alloy

(2) Professional service

(3) Reasonable price and first class quality

(4)OEM Service for more than 10 years

Maching

1. We will produce the samples according to the confirmed casting process.

2. We will send the test reports and photos to our customers after checking.

3. We will do the production based on the production tracking table after the sample being approved.

4. The inspector should track the quality and time of the products during the producing.

5. Do the finial inspections to the products and send the relevant data and finished products' photos to the customers.

Service

drawings→mould making→raw casting→sandblasting→rough machining or finish machining→surface treatment→packing→delivery

metarial | process | Weight | Standard |

Cast iron | clay sand casting, furan resin sand casting, shell mold casting | 0.5-5000kg 50-5000kg 0.3-20kg | GB ISO ASTM DIN JIS |

water-glass sand casting, water-glass investment casting, lost-wax investment casting | 5-1500kg 0.05-50kg | ||

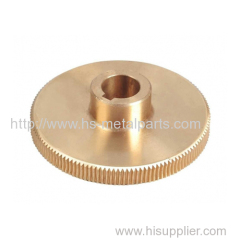

Non-ferrous metals | Die casting, sand casting, lost-wax casting | 0.1-200kg 0.3-20kg |

Casting process | Materail |

ASTMA148class80-40, ASTMA148Class80-50 A572GR60, AISI316 stainless steel, ST52, S355, GS-52.3, ASTMA48Class30B CK45, 1.7218-25CrMo4 | |

GGG50,GGG30, ASTMA48 class25B, 42CrMo4, C22 ductile iron 65-45-12, AlCuMgpbF34, EN-JIS-500-7 EN1563 , EN10293-GE300 HT200, DIN17205-GS-25CrMo4 | |

C1040 ,Alsi12 |

OUR ADVATANAGE

(1)We have many experience for 10 years in the casting .

(2)We can supply all kinds of castings according to drawing, sample or specific industry standard.

(3)We would offer our professional and warm-hearted service.

(4)Strong engerneering team makes high quality

(5)We have many international advanced-level equipments such as CNC maching center ,CMM,testing equipments and so on

(6)OEM services

HS Machinery Parts is a factory producing steel castings, iron castings, aluminum castings, brass castings, bronze castings, forgings, stampings, and machined parts with material carbon steel, alloy steel, stainless steel, aluminumalloy, copper alloy such as brass and bronze. Products more than 85% export toUSA, Europe, and other countries, and quality obtained very good reputation from our customers. Electric zinc, hot dip zinc plating, power coating, painting, phosphatization are the most common anti rust surface treatment, others you can specify.

Welcome to send us your drawings and requirement, we'll offer you the best quality products but in competitive price.